Environmental technologies

Strengthen initiatives for the materials in power semiconductors that contribute to decarbonization and carbon neutrality

In the initiatives for decarbonization and carbon neutrality as part of the latest and largest social issues, Countries plan investments of nearly ¥500 trillion over the next ten years.*1 In addition, GFANZ*2 plans investments and loans of approximately ¥11 quadrillion (US$100 trillion) through a coalition of voluntary financial Institutions from Japan and overseas. These represent major expectations in the resolution of issues by firms and businesses around the world. Under these circumstances, the market scale of power semiconductors is expected to further expand as the heart of EV/HEV and energy-saving home appliances while supporting the renewable energy systems of wind power and solar power generation, as well as efficient power transmission and supply based on smart grids.

※1 Source: JEITA Semiconductor Subcommittee, “Semiconductor Strategies for Achieving Increased International Competitiveness”

※2 Glasgow Financial Alliance for Net Zero (GFANZ): a global coalition of more than 450 leading financial institutions that officially took effect at COP26 in Glasgow, UK, in 2021

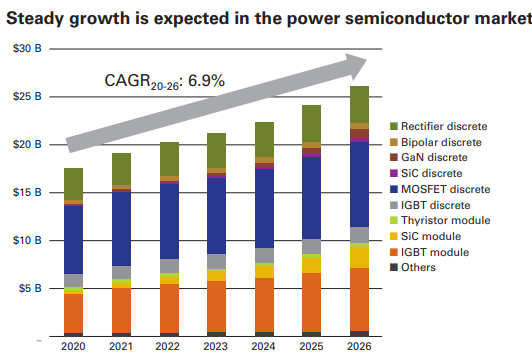

One of the triggers leading the unprecedented growth of the semiconductor industry — Power semiconductors

Growth in the power semiconductor market has started to accelerate and has now become one of the triggers leading the unprecedented growth of the semiconductor industry TOK has the largest global market share of g/i-Line photoresists, which are essential for the manufacture of power semiconductors, and consistently account for 7% to nearly 10% of consolidated net sales. At present, TOK continues mass production at full capacity in response to the market growth of power semiconductors. Under the TOK Medium-Term Plan 2024, the Company promotes large-scale capital investments to increase equipment and efficiency in manufacturing plants (automation and mechanization) and to renew the manufacturing, inspection, and warehouse equipment.

Source:

Status of the Power Electronics Industry 2021 report,

Yole Developpement, 2021

Developing high-value-added/next-generation materials

In order to steadily advance initiatives for decarbonization and carbon neutrality and thus limit global warming to 1.5°C, the further upgrading and performance increase of power semiconductors are required. To this end, TOK is committed to providing and developing new high-value-added and next-generation materials. TOK developed proprietary i-Line thick-film photoresists of the chemically amplified type for the growing demand for high-performance power devices. The Company is also striving to develop materials for next-generation SiC (silicon carbide), GaN (gallium nitride), and Ga2O3 (gallium oxide) power semiconductors.

Long-run creation of shared value

The market for g/i-Line photoresists and other power semiconductor materials consists of many customers involving long-term transactions. TOK pursues long-term sustainable growth by maintaining relationships of trust on a long-term basis. Moreover, the amount and thickness of g/i-Line photoresists vary by customer, in addition to substantial differences in the amounts used. By continuously providing detailed service under the proprietary customer-oriented strategies, the Company will create long-run shared value toward decarbonization and carbon neutrality.

Develop in-house recycling ecosystem based on “chemical looping”

As a new initiative, we strive to develop an in-house recycling ecosystem based on chemical looping.

Collect super-high-concentration CO2 without using air for reaction

TOK discharges organic solvent effluents generated in the manufacturing process after partial recycling, combustion, and detoxification. Usually, the separation and recovery of CO2 through the normal combustion of effluents in the air takes considerable

energy because the CO2 in the exhaust gas is only approximately 13%* due to the large shares of atmospheric O2 and N2 that are not used for combustion. In addition, atmospheric N2 is oxidized through combustion. In general, a thermal power plant is considered to emit 30 to 100 ppm of thermal NOx after denitration treatment.

In contrast, TOK is developing a system based on chemical looping, where atmospheric oxygen is not used in the reaction, and high-concentration CO2 can be selectively collected by controlling and optimizing reactive conditions. This system can also

minimize thermal NOx because the reaction temperature is lower than for normal combustion. Investigations using present experimental equipment have indicated a CO2 conversion efficiency of 95% or higher and a NOx level of approximately 1 to

10 ppm (lower measurement limit at present), demonstrating the superiority of this system. Currently, joint research with universities and other research institutions is in progress toward in-house practical application of this system. Subsequently, we will also pursue energy recycling and CO2 conversion linked to this system.

The system still has many problems to clarify, we will persistently continue with long-running development as our characteristic as part of our contribution to decarbonization.

* Calculated values

Related Material Issue