Image Sensor / MEMS Manufacturing Field

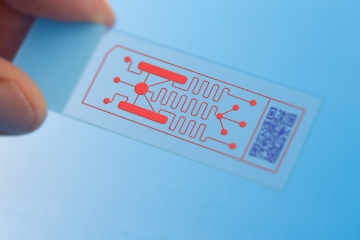

The TOK Group’s various products contribute to manufacturing more compact and sophisticated electronic devices including image sensors, key components of smartphone cameras, and BAW filters that is part of antenna.

Micro-lenses

that support high-resolution cameras

For image sensors that convert the brightness and darkness of light into electrical signals, improving

the efficiency with which light is collected from the outside is vital.

Micro-lenses that make this possible are an indispensable component of image sensors and

underpin the evolution of cameras capable of taking photographs of ever-higher resolution.

We also provide products for making micro-lenses,

which serve as the indispensable eyes of a wide

variety of high-definition cameras.

CMOS sensors

Driving support system

TOK’s products in Image Sensor / MEMS Manufacturing Field

Core Technology

The world leading micro-fabrication and high purification technologies

Our products, which are used to semiconductor manufacturing featuring cutting-edge circuits produced at a scale of several nanometers, are supported by two global-leading core technologies.